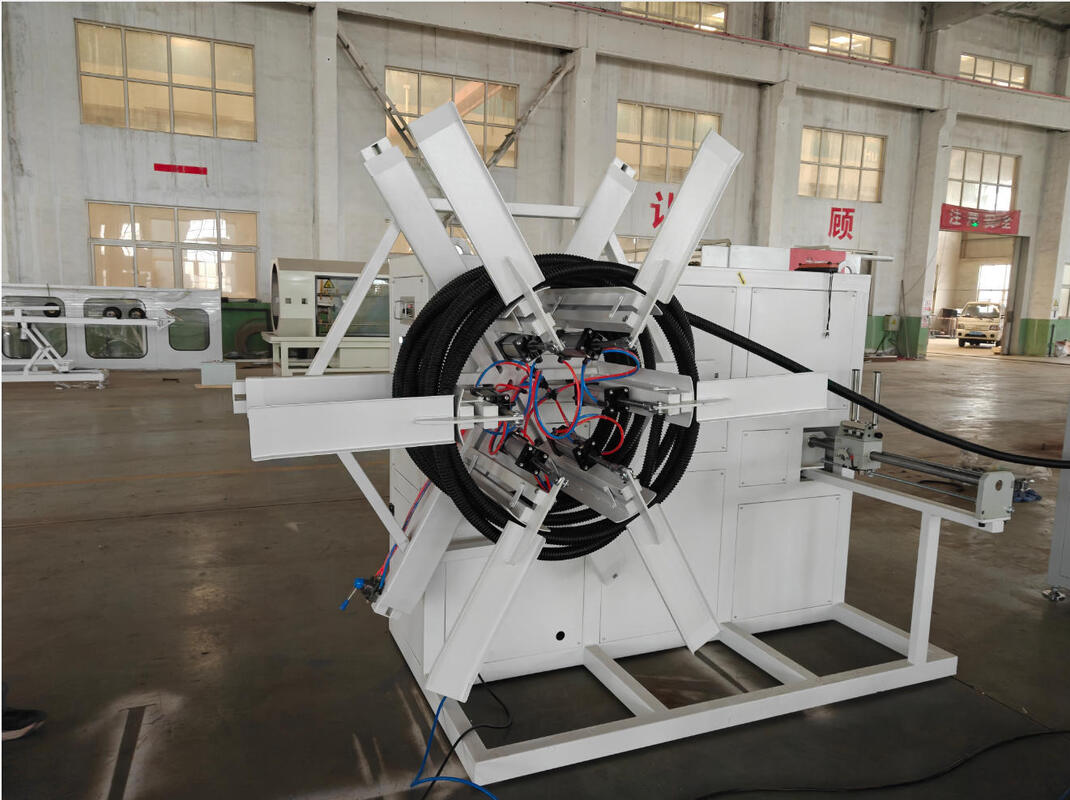

Machine d'extrusion de tubes ondulés simple paroi automatique

La Ligne d'extrusion de tuyaux ondulés simple paroi est un système très efficace et fiable conçu pour produire des tuyaux ondulés simple paroi de qualité supérieure avec une consistance exceptionnelle. Conçue pour répondre aux diverses exigences industrielles, cette ligne de production fournit des solutions de tuyauterie durables et flexibles, idéales pour les applications de faisceaux de câbles automobiles et d'autres secteurs exigeants.

Principales caractéristiques

- Nom du produit : Ligne d'extrusion de tuyaux ondulés simple paroi

- Moules disponibles : ID75mm, 100mm, 125mm, 150mm

- Automatisation : Fonctionnement entièrement automatique

- Capacité de production : 40-80 kg/h

- Matériaux recommandés : Nouveau matériau pour PE, PP, PVC

- Conçu par des spécialistes de premier plan des machines à tuyaux ondulés

- Idéal pour les applications de lignes de production de faisceaux de câbles automobiles

- Permet la fabrication de tuyaux simple paroi à grande vitesse avec une qualité constante

Spécifications techniques

| Paramètre |

Spécification |

| Type de commercialisation |

Produit ordinaire |

| Production |

Stable et à grande vitesse |

| Sortie |

40-80 kg/h (Convient à l'usine de fabrication de tuyaux ondulés simple paroi) |

| Taille maximale des tuyaux |

110 mm |

| Matière première recommandée |

Nouveau matériau pour PE, PP, PVC |

| Moteur |

Siemens |

| Moules |

ID63mm, 75mm, 90mm, 110mm |

| Degré d'automatisation |

Entièrement automatique |

| Système de refroidissement |

Refroidissement par eau |

Avantages de la production

Cette ligne d'extrusion est dotée d'une technologie de pointe et d'une construction robuste pour garantir une production stable et à grande vitesse tout en maintenant un contrôle précis sur les dimensions des tuyaux et la finition de surface. La polyvalence du système en matière de gestion de plusieurs tailles de moules permet aux fabricants de produire des tuyaux de différents diamètres en fonction des exigences spécifiques.

Compatibilité des matériaux et qualité

La ligne est optimisée pour une utilisation avec des matières premières de haute qualité, notamment le PE (polyéthylène), le PP (polypropylène) et le PVC (chlorure de polyvinyle). Ces matériaux fournissent des tuyaux finis avec une excellente flexibilité, une résistance aux contraintes environnementales et une durée de vie prolongée.

Technologie de refroidissement

Le système de refroidissement par eau intégré refroidit rapidement et uniformément les tuyaux extrudés lorsqu'ils sortent de la filière, maintenant l'intégrité structurelle et assurant des surfaces ondulées lisses. Cette technologie contribue à des vitesses de production plus rapides et à des temps de refroidissement réduits.

Applications industrielles

Ce système de production de tuyaux économe en énergie est largement utilisé dans de nombreux secteurs, notamment :

- Systèmes de drainage

- Conduits de protection des câbles

- Gestion des eaux usées

- Irrigation agricole

- Production de faisceaux de câbles automobiles

Certification et normes : Équipement certifié CE et ISO garantissant la conformité aux normes internationales de qualité et de sécurité.

Fabrication et livraison

La ligne d'extrusion de tuyaux ondulés simple paroi HUASU est dotée d'un emballage standard pour conteneurs pour un transport en toute sécurité, avec une capacité d'approvisionnement de 100 ensembles par an et une livraison dans les 60 à 90 jours. Des conditions de paiement flexibles, notamment T/T et L/C, sont disponibles pour les clients internationaux.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!